What are Tungsten Carbide and its Advantages?

Tungsten carbide alludes to the combination, which is made by blending tungsten with different substances. To make tungsten more moldable, it is blended in equivalent parts with carbon to shape a powder and afterward joined with a cover like nickel, Carbide Button, or cobalt. The subsequent Tungsten Carbide Button metal is known as tungsten carbide and can be formed into different things, like wedding rings, golf clubs, and saw cutting edges.

Tungsten vs. Tungsten Carbide Durability

While tungsten carbide has many of its properties, including its solidness, strength, and high softening point, it is a vastly improved metal.

Tungsten is positioned at 7.5 on the scale. It is challenging and sturdy yet can, in any case, get scratched and harmed over the long run. Tungsten carbide is amazingly scratch safe and is the hardest metal for use in adornments.

Tungsten carbide is profoundly sturdy since they don’t handily get scratches or lose their gloss. Tungsten carbide rings, be that as it may, can’t be resized and should be changed if the ring turns out to be excessively close or excessively free.

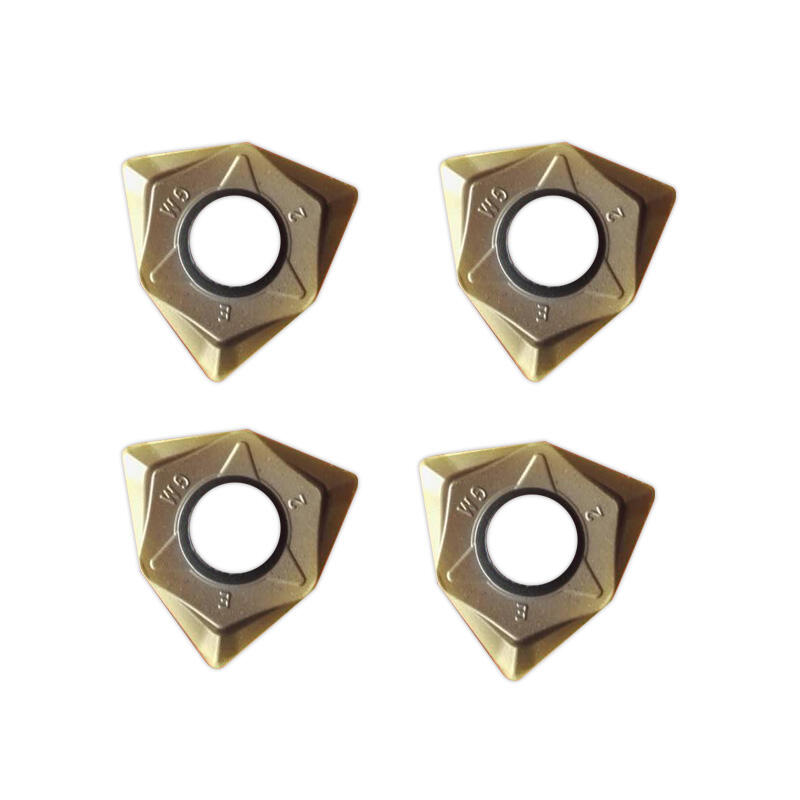

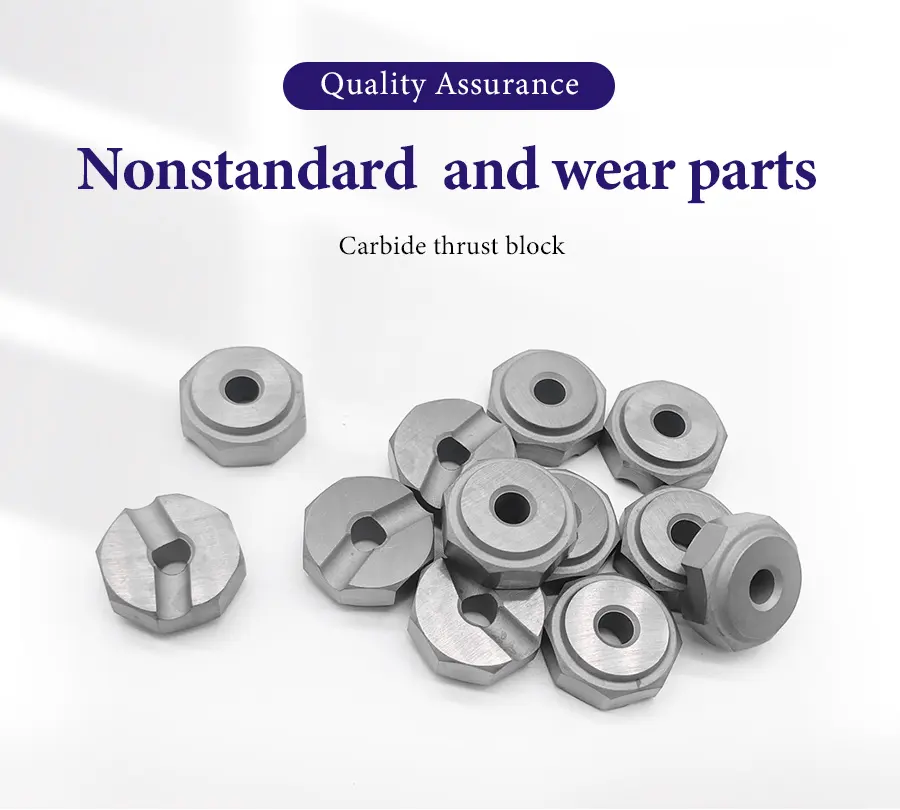

Tungsten Carbide Plate is one of the numerous materials of tungsten steel made by metallurgical techniques, such as crushing, ball processing, squeezing, and sintering. The piece substance of WC and CO in various employments of carbide plates is not steady. It is generally utilized.

Components of Cemented carbide bar:

1. High strength and high hardness.

2. Superb hardness, wear-obstruction, high versatile modulus, high flexural strength,

3. Great compound soundness (corrosive, antacid, high-temperature oxidation), sway opposition,

4. outstanding strength, low coefficient of extension, and so forth

Uses of carbide plate

The carbide plate is appropriate for making drawing bites the dust center, wear-safe parts, and stepping embellishments and kicks the bucket centers for solidified carbide programmed press. It has great strength and effect durability and low wears opposition. However, the top manufacturing kick the bucket with an enormous burden; for example, the top fashioning pass on for screw, bolt, and so on, is additionally utilized for stepping bites the dust, expulsion bites the dust, punching bites the dust, and so forth.

Before buying a tungsten carbide band, check with the seller about the metals remembered for the composite. Respectable sellers should give you this data. For example, tungsten carbide with nickel is viewed as of good quality and, furthermore, hypoallergenic.

Conversely, most merchants will utilize the terms tungsten and tungsten carbide, and some can sell sub-par combinations at more exorbitant costs. This is the reason purchase from a trustworthy seller and to acquire data about the preceding metal buy.

Why pick Zhuzhou Kerui Cemented Carbide?

We will maintain the “client first, meets the prerequisites, consistent improvement, the quest for five stars” approach, in close participation with clients, in the wild market rivalry, a shared benefit, and normal turn of events. Clients and the local area welcome to our organization for specialized exhortation contact a business and work together.

Buy one of the best qualities of carbide and tungsten from the top company – https://www.keruicementedcarbide.com/

For more information contact us!